IONICS High-Frequency X-ray Source for NDT Systems

Home | Resources

High-Frequency X-ray Source for NDT Systems

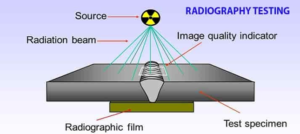

When it comes to non-destructive testing (NDT), having the right source for the system can make all the difference. At IONICS, we’ve created power supplies for OEMs needing continuous NDT inspection. Our compact, high-frequency units when connected with the X-ray tube, generate precise X-rays needed for quality control in science and industry, ensuring top-notch evaluations and troubleshooting.

Our X-ray source, available in 125kV, 160kV, and 220kV models, with high-frequency output when connected to an X-ray tube, outperforms traditional power supplies.

|

Model |

Voltage Output |

Current Output |

|

HV125K625W |

125kV |

5mA |

|

HV160K800W |

160kV |

5mA |

|

HV220K1.1K |

220kV |

5mA |

The high-frequency of 40kHz of our X-ray source ensures exceptional imaging capabilities, providing detailed, high-resolution scans of the target material. Whether you’re conducting weld inspections, pipeline assessments, or aerospace component evaluations, IONICS has the X-ray Source required to enhance the performance of your NDT system.

Key Features of IONICS X-ray Source

Some of the key features of our source include:

High-Resolution Imaging

IONICS’ X-ray source provides exceptional image clarity and detail due to

high-frequency (40kHz) & low ripple, ensuring precise defect detection and accurate analysis in NDT

Compact and Portable Design

Designed for mobility and accessibility, IONICS’ HF Source are lightweight and easy to transport in various testing environments, whether in the lab or on-site

Easy Integration

IONICS HF Source is designed for seamless integration with NDT Systems, facilitating quick setup and minimal downtime

High Penetration Capability

Capable of penetrating dense materials, providing reliable results even in challenging inspection scenarios

Applications of IONICS X-ray Generators in NDT

IONICS’ X-ray source finds a wide range of applications in non-destructive testing across various industries. In the manufacturing sector, these generators are commonly used for weld inspection, allowing for the detection of cracks, porosity, and other defects without damaging the weld.

Weld Inspection

With IONICS’ X-ray source, manufacturers can perform thorough weld inspections to ensure structural integrity. This non-destructive method helps identify and fix issues early, enhancing quality control and product reliability.

Aerospace Inspection

In the aerospace industry, IONICS’ X-ray source helps the system inspect critical components like aircraft structures and engine parts. This non-destructive method ensures safety and reliability, allowing manufacturers to catch and fix issues early.

Automotive Parts Inspection

With IONICS’ X-ray source, manufacturers ensure automotive part quality. This non-destructive method detects issues early, improving reliability and quality control.